Friday, 29 April 2016

Changing a Return’s Vessel

While on the return booking in screen (R003), there is a new button on the left side which allows the operator to cycle through the available dispense vessels, from smallest capacity to largest capacity. The current vessel capacity is displayed at the top of the screen. The selected vessel will be saved as the return’s vessel when pressing the save button.

This feature is available from version 1.9.20, upgrade is free for all customers with a remote support contract. Contact Rexson to arrange an update.

Tuesday, 28 August 2012

Adding Returns Using Barcode Scanner

Booking returns into CPC using a barcode scanner is the simplest and most efficient method of booking in returns. To use this method you need printed dispense labels containing a barcode of the dispense batch number and a barcode scanner.

Go to the Returns screen from the main menu. This screen automatically intercepts any scanned barcodes and checks if they are dispense batch numbers.

Place the vessel on the scale and scan the barcode of the product to return. If the barcode is recognised as a valid dispense batch, the Add Return screen will be displayed as below:

The details of the dispense will be completed automatically, including the original dispense vessel empty weight, the formula code and job number (if the original dispense was booked to a job). The total scale weight will be read and the net return weight will be calculated based on the original empty vessel weight.

Enter a return location if required.

Press the Save button. You will be prompted to print a return label if required.

You will be returned to the main returns list ready to book in another return.

Monday, 14 March 2011

Using Press Returns When Working With Jobs On ColorPoint Console

There are a number of ways to work off press returns on CPC. This post outlines the most efficient route when dispensing to jobs.

Select Job Item to Dispense

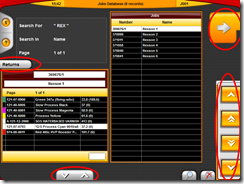

Go to the jobs screen and navigate to the job required using the navigation buttons on the right side of the screen.

A job consists of one or more job items. Each job item is a formula. The numbers to the right of the formula name indicate how much ink is estimated for this item and in brackets how much has already been issued against the job.

The panel at the left displays the job items on that job. Use the navigation buttons below the job panel to navigate up and down within the list of job items. When you navigate through the job items, a check is made against the returns database for the formula code of the currently selected job item. If a return with the same formula code is present, the “Returns” button will appear on the left side of the screen.

Pressing the “Returns” button will take you the returns database with the list filtered to the current formula code. Here you will be able to see all matching returns. If there are any returns that are a suitable size, you can issue them to press from here directly instead of topping up, remixing or dispensing new ink.

If there are no suitable returns and you need to dispense new ink for your formula press the select button at the top right. This will take you to the dispense screen.

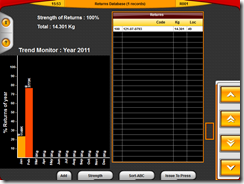

The returns selection process in the dispense screen is more thorough. Once the required weight is known a check is made for any return that can be made into the target formula, not just returns with a matching formula code. If any returns can be recycled, the “Available Returns” button glows red.

To dispense without recycling any returns, just press “Start” or “Top-up” depending on the type of dispense needed.

To recycle returns in the current dispense press the “Available Returns” button.

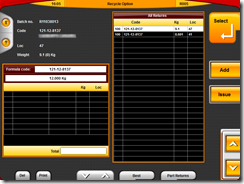

In the returns screen you are presented with the list of whole returns that can be used. These returns will be fully converted into the target formula with nothing remaining. The advantage of this is that you may use the same vessel as the return is already in and simply top up to the required weight instead of decanting into a new vessel.

If no suitable return is listed, or you want to use part of a larger return first, press the “Part Returns” button on the lower edge of the screen.

Here the return will have to be poured into the dispense vessel. The list shows the weight of the return that will be used up. The detail panel on the left shows the actual weight of the return. On the screen shot it can be seen that 7.068kg of return will be used from a total size of 17.2kg.

To add a return to the list to be recycled press the “Add” button on the right. You may continue to add returns until there is no more remaining weight available to recycle them.

If you want to maximise the amount of returns recycled press the “Best” button. This attempts to recycle as much material as possible. Be aware that this could lead to having to manually add up to 8 or nine small returns, so this may not be the most efficient method for you to use.

Here “Best” has been selected, resulting in 3 returns being added for recycling. To continue press the “Select” button.

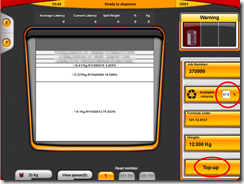

When the first return in the selection is a whole return, you will be given the option to use the return vessel for dispensing. Select yes if you want to dispense into the return, select no if you want to manually add the first return to a new vessel. Subsequent returns will always be added manually.

After making your selection you will see the dispense screen again. Notice that the “Available Returns” button is no longer red, and the recycled material amount has been filled in. In this case 97.8% of the ink will be recycled ink, with the remainder being new ink.

The “Start” button has changed to “Top-up” to indicate that you will be topping up an existing press return rather than using an empty vessel.

Press the “Top-up” button to begin dispensing.

If you change the weight to be dispensed, this will reset the returns list and remove them all from the selection. The “Available Returns” button will glow red again if returns are available for this new weight. This happens because with a different weight parameter some returns will no longer be viable for remixing, and the selection should be made from the updated returns list.

Wednesday, 2 February 2011

Issue returns, materials and formulas on ColorPoint Manager

Returns are usually used at CPC by reworking into other formulas or issuing them directly to press. For convenience the returns may also be issued to press, booked against a job.

There are two ways of issuing items to a job. The first is job centric; find the job you are looking for, open it and use the ‘Issue to Job’ action. The second is better if you need to issue items across a number of jobs; open Tools | Issues | Issue to Job from the menu bar.

In the second option the job is selected from a drop down list allowing any job to be selected, in the first option the job selector is hidden as the job number is taken from the currently selected job.

The following details need to be selected or filed in to complete the issue:

- Screen: the screen on the press that the item is being issued to.

- Weight: the weight to be issued.

- Date: the date and time of the issue, defaults to the current time.

- Only show items that are part of this job: restricts the selection of items that may be issued to those that are already on the job items list. Un-ticking this option will allow you to book and formula to any screen and is not recommended unless you are certain it is required.

- The item type that is being booked to the job:

- Material: select a material and the material batch of the pack/barrel being used to supply it.

- Formula: Select the formula code that is being issued. This is used with pre-made formulas, or formulas that are already held in stock.

- Return: Select the required return from the list. The return stock will be debited with the weight issued.

Clicking ‘Reset’ will reset the form, clicking ‘Issue’ issue the selection and resets the form.