Overview

ColorPoint checks that the correct dispense vessel is on the scale before starting as dispense. To aid detecting that the correct vessel is on the scale, a number of parameters are set for each vessel size.

Below is an example of a dispense vessel:

- Capacity: 20 Kg

- Volume: 20 l

- Minimum Empty Weight: 0.8 Kg

- Maximum Empty Weight: 1.0 Kg

- Nominal Weight: 0.85 Kg

- Lid Weight: 0.1 Kg

- Default Vessel for Head

Capacity

The maximum weight the vessel can hold. This is also used to identify your vessel, and for overflow calculations.

Volume

The maximum volume your vessel can hold. This is used for overflow calculations.

Minimum and Maximum Empty Weight

The minimum and maximum weight a vessel of this type should weigh. This is used to detect that the vessel you have selected to use is the vessel on the scale. If an empty 20 Kg vessel is placed on the scale, it must weigh between 0.8 and 1.0 Kg, otherwise the “Wrong Vessel On Scale” icon will be displayed:

It is important that the range of weight between the minimum and maximum empty weight is kept as small as possible, as this makes handling the vessel more accurate. It is also important the vessels weight ranges do not overlap, e.g. a 25 Kg vessel with a weight range of 0.9 to 1.1 kg could be confused with the 20 Kg vessel and incorrectly detect the 20 Kg capacity as 25 Kg, allowing the user to potentially overfill the vessel.

Nominal Weight

The nominal weight defaults to the mid-point between the minimum and maximum empty weight, but may be different. It should be set to the value that you expect a brand new empty vessel to weigh. This value is used as the vessel weight in situations where the original empty vessel weight is unknown, e.g. booking in a return without the original dispense data.

Lid Weight

This value helps to accurately determine the weight of returned ink in a vessel. The lid weight is used if returns are booked in with the lid on. If returns are booked in before the lid is put on, set the value to 0 Kg.

Default Vessel For Head

This setting is only used on multi head dispensers where the scale size differs between heads, e.g. 300 Kg on Head 1 and 35 Kg on head 2. It is used to override the vessel selection when a vessel to large for the scale is selected. Setting this in other situations has no effect and it can be ignored.

Other Useful Information

No vessel on scale

When the scale weight is below 0.1 Kg the no vessel on scale warning icon will be shown.

![clip_image001[4] clip_image001[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhMOuCcXq35KtxgQK6YPw_LwKask9F_1exglBF0Ga8emEv-nnaBb6qEYA7B7AoepBzOWPyKehiZoH9vgyu5rIkpra_nApWynXaVdix8A1f_Qpr_Kl6nJ5j9bFa3Erk5jPnSVihylh14amaW/?imgmax=800)

If you see this icon and there is a vessel on the scale, it is possible that the scale was zeroed while the vessel was on the scale, especially if the vessel was on the scale when the system was started.

Unknown Vessel On Scale

If the vessel on the scale does not match the weight range of any know vessel, the unknown vessel icon is displayed.

![clip_image001[6] clip_image001[6]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEi5jtLUzbJVxvoE9rVuWQCD5Wg_jCoyngpilFi4NLfZL1mUpd55gvsUgKn16MVqzkaMKJJX7gRil6975i6qxwrcGYfM7gr3OWPrU2sJIynPCF5xMxJ8imWljwslPjIKaKiGWtbQ-iMe0Z8h/?imgmax=800)

This often indicates the the vessel on the scale is not empty, and that the top-up function should be used.

Vessel Overfill

This icon indicates that the amount selected is too large for the vessel selected.

![clip_image001[8] clip_image001[8]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEid257u8Dkolisz1mMH9XtlyzUB6EBvuOyvN4dWnrLNhFFhnqFUVW-sHlGFmg0LJVGRZhDNi6uFKR6iy4sQWwvYq-QHd2OkUlFq4-K0bbBHMSXonjCEf_PxJZ1PENZM7iZr2s5kYX0qYE9m/?imgmax=800)

This often indicates the the vessel on the scale is not empty, and that the top-up function should be used.

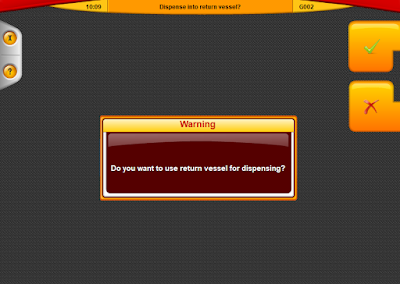

icon indicates that the Return

vessel is being used. The dispense is

set as a top up and all other materials will be dispensed on top of the

existing Return.

icon indicates that the Return

vessel is being used. The dispense is

set as a top up and all other materials will be dispensed on top of the

existing Return.

![clip_image001[4] clip_image001[4]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhMOuCcXq35KtxgQK6YPw_LwKask9F_1exglBF0Ga8emEv-nnaBb6qEYA7B7AoepBzOWPyKehiZoH9vgyu5rIkpra_nApWynXaVdix8A1f_Qpr_Kl6nJ5j9bFa3Erk5jPnSVihylh14amaW/?imgmax=800)

![clip_image001[6] clip_image001[6]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEi5jtLUzbJVxvoE9rVuWQCD5Wg_jCoyngpilFi4NLfZL1mUpd55gvsUgKn16MVqzkaMKJJX7gRil6975i6qxwrcGYfM7gr3OWPrU2sJIynPCF5xMxJ8imWljwslPjIKaKiGWtbQ-iMe0Z8h/?imgmax=800)

![clip_image001[8] clip_image001[8]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEid257u8Dkolisz1mMH9XtlyzUB6EBvuOyvN4dWnrLNhFFhnqFUVW-sHlGFmg0LJVGRZhDNi6uFKR6iy4sQWwvYq-QHd2OkUlFq4-K0bbBHMSXonjCEf_PxJZ1PENZM7iZr2s5kYX0qYE9m/?imgmax=800)