Recently we have added an additional column to the formula items screen to make adding materials at a fixed % easier.

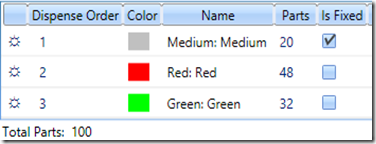

When you tick the ‘Is Fixed’ column for a given material it means that the parts of that item will not be changed when the formula items are re-apportioned. This is useful for scenarios where you know that a certain material must always make up a certain percentage of a formula. So if you increased the parts of the red in the screenshot above to 60 and then had the software reapportion the formula (which it would do automatically when you pressed the save button), the result would be as follows.

As you can see the green has become roughly 1/3 smaller than the amount of red but the amount of medium in the formula has been unaffected. This feature was in previous versions of ColorPoint Manager but was specified as a property of the material and once a material was marked as being a fixed % additive it was considered fixed in every formula. The new system is more flexible in that it allows materials to be made fixed on a case by case basis. It is important to note that ticking the ‘Is Fixed’ check box does not mean that you will not be able to change the parts of the material manually, only that they will not be changed when the formula is re-apportioned.